Description

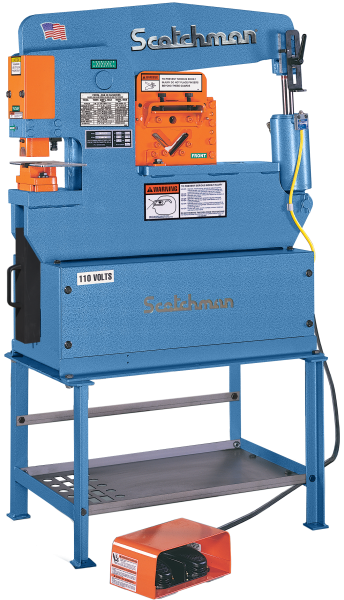

70 Ton Brand New Scotchman Dual Operator Ironworker, Model DO 70/110-24M

70 Ton Brand New Scotchman Dual Operator Ironworker, Model DO 70/110-24M, Dual Operator Allows For Two Operators To Work At The Same Time At Full Capacity, 70 Ton Punch Station (1-1/8″ in 3/4″), Keyed Punch Ram For Safety, 9″ Throat Depth, Punch Gauging Table with Fence & Scale, Die Holder Complete With 2″ Die Insert, Punch Nut With Wrench & Stripper, Adjustable Swing-Away Stripper, One Round Punch & Die: Max. Diameter 1 – 1/4″, Punch Jog Control, 2 Adjustable Electric Stroke Controls with Scale, 2 Electric Remote Foot Pedals, Two 2-Stage Hydraulic Pumps, 2 Valves, Notcher Table with Guides, Shear Table With Miter Fence, Tool Table Work Area, Slug Receptacles, Electrical Box Supplied with Emergency Palm Button & Lock-Out Tag-Out Accommodations, All Guards Necessary, Forklift Accommodations, MADE IN USA

***Please Call 854-871-8341 For More Information***

DETAILED SPECIFICATION

| Punch Capacity | 70 Ton, 1-1/8″ in 3/4″ |

|---|---|

| Special Tooling | 4″ Max. Dia. |

| Throat Depth | 9″ |

| Flat Bar Shear (Sabre Blade-Std.) | 110 Ton, 24″ Length |

| 1″ x 6″ | |

| 3/4″ x 10″ | |

| 1/2″ x 14″ | |

| 3/8″ x 24″ | |

| Angle Shear 90 Degrees | 6″ x 6″ x 1/2″ |

| Angle Shear 45 Degrees | 3″ x 3″ x 3/8″ |

| Angle Shear 45 Degrees (With Bar Shear) | 4″ x 4″ x 1/2″ |

| Square Rod (Max.) | 1/4″ To 1″, 1 Cavity |

| Brake 12″ | 65 Ton |

| Brake 24″ | 45 Ton |

| Open End Brake (Flat Or Angle Iron) | Max. 1/4″ x 6″ |

| Pipe Notcher (Schedule 40 I.D.) | 3/4″, 1″, 1-1/4″, 1-1/2″, 2″ |

| 90 Degree V. Notcher | 6″ x 6″ x 5/16″ |

| Rectangular Notcher | 3″ x 5″ x 3/8″ |

| 3″ x 4″ x 1/2″ | |

| V. Notch | 3″ x 3″ x 3/8″ |

| Notching In Leg Of Channel | 6″ To 10″ |

| Channel Shear | 2″ To 6″ Adj. |

| Strut Shear | Samples Required |

| Rod Shear | |

| Round Rod (Max.) | 1/4″ To 1 -1/4″, 9 Cavity |

| Square Tube Shear | 1/2″ to 2″, 12″ Gauge |

| Picket Tool | 1/2″, 3/4″, 1″, 16 Gauge |

| Offset Die Holder | Max. 40 Ton |

| Strokes Per Minute In Light Material | 1/4″ Stroke [Punch Station] |

| Strokes Per Minute In Heavy Material | 3/4″ Stroke [Punch Station] |

| Hydraulics | 3000/3000 psi |

| Warranty | 3 Years on Parts |

| Motor Standard | 10 H.P., 3ph |

| Voltage | 208/230/380/460/575 – 3 Phase |

| Dimensions (L x W x H) | 65″ x 30″ x 72-1/8″ |

| Weight | 3800 lbs |

EQUIPPED WITH

| 70 Ton Punch Station (1-1/8″ in 3/4″) |

| Dual Operator Allows For Two Operators To Work At The Same Time At Full Capacity |

| Keyed Punch Ram For Safety |

| 9″ Throat Depth |

| Punch Gauging Table with Fence & Scale |

| Die Holder Complete With 2″ Die Insert |

| Punch Nut With Wrench & Stripper |

| Adjustable Swing-Away Stripper |

| One Round Punch & Die: Max. Diameter 1 – 1/4″ |

| Punch Jog Control |

| 2 Adjustable Electric Stroke Controls with Scale |

| 2 Electric Remote Foot Pedals |

| Two 2-Stage Hydraulic Pumps |

| 2 Valves |

| Notcher Table with Guides |

| Shear Table With Miter Fence |

| Tool Table Work Area |

| Slug Receptacles |

| Electrical Box Supplied with Emergency Palm Button & Lock-Out Tag-Out Accommodations |

| All Guards Necessary |

| Forklift Accommodations |

| MADE IN USA |

Reasons to buy a Scotchman

- Scotchman is Made in U.S.A. — and we can prove it!

- Scotchman offers the Best-in-the-Business 3 YEAR-WARRANTY!

- Scotchman has a SAFE punch & die change out.

- Scotchman punch is guided through a true vertical guide block.

- The punch can be safely left in a Scotchman ironworker while using the Angle Shear.

- The punch can be safely left in a Scotchman ironworker while using the Flat Bar Shear.

- The brake can be used without removing the punch on a Scotchman ironworker.

- A Scotchman Pipe Notcher can be used on the tool table without removing the punch.

- The Scotchman punch is Keyed to prevent shaped punches from spinning making it a SAFER machine.

- Scotchman ironworkers have a larger capacity angle shear.

- Calls made to Scotchman are answered by a person, not a machine.

Scotchman prides itself in manufacturing QUALITY, DEPENDABLE, AMERICAN Ironworkers.