Description

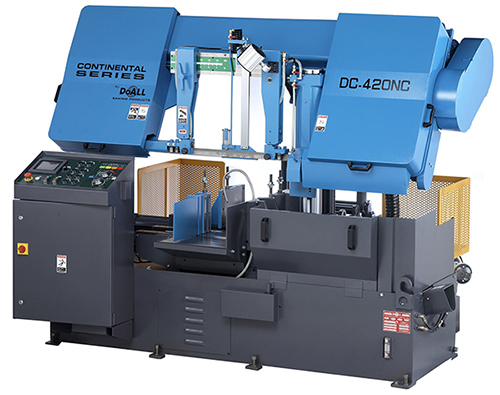

16″ x 16″ DoALL Continental Series Fully Automatic High Production Horizontal Bandsaw, Model DC-420NC

16″ x 16″ DoALL Continental Series Fully Automatic High Production Horizontal Bandsaw, Model DC-420NC, NC Control Panel: Touch Screen Control, 20 Job Presets, Multiple Language Capability, Trouble Shooting Prompts, Easy Operation, PLC Control for All Electric and Hydraulic Functions, Infinitely Variable Speed Controlled by VFD, Hydraulic Retractable Shuttle Vise Material Indexer, Rapid and Creep Speed Index Vise Control, Multi-Step Full Stroke Vises with Split Front Vise and Variable Vise Pressure Control, High Efficiency Transmission, Nesting Fixture for Bundle Cutting, Spring Loaded, Zero Clearance, Coolant Through, Carbide Faced Saw Guide with Lead-In Rollers, Power Driven, Coolant Flushed, Blade Cleaning Wire Brush, Flushing Hose and Auxiliary Coolant Nozzles, Hydraulic Blade Tensions, Automatic Chip Conveyor, Blade Breakage/ Stall Motion Detector Shut Off Switch, Band Door Interlocks, Hydraulic System, Work Light, One 6′-1/2″ Conveyor, Set Up Tools and Tool Box, One DoAll Bi-Metal Saw Blade, Complimentary DoAll Cutting Fluids Package

***Please Call 854-871-8341 For More Information***

DETAILED SPECIFICATION

| Overall Capacity | 16″ x 16″ |

|---|---|

| Operation | Automatic |

| . | |

| Capacity | |

| Round | 16-1/2″ |

| Rectangle | 16-1/2″ x 16-1/2″ |

| Bundle Capacity Max. | 14-1/2″ x 7-5/8″ |

| Bundle Capacity Min. | 6-1/2″ x 3-1/4″ |

| Blade Speed | 72 – 390 SFPM |

| Blade Size | 1-1/2″ x 0.05″ x 192″ |

| Material Pass Line Height | 27-1/2″ |

| Automatic Indexing Lengths: | |

| Single | 19.68″ |

| Multiple | 177.16″ |

| Remnant Length | Single Piece (Non-Bundle) |

| 4.33″ | |

| Coolant Pump Horsepower | 1/4 H.P. |

| Coolant Tank Capacity | 26 Gallons |

| Hydraulic Pump Horsepower | 2 H.P. |

| Hydraulic Tank Capacity | 22 Gallons |

| Horsepower | 10 H.P. |

| Voltage | 230V ~ 3 Phase |

| Dimensions (W x D x H) | 88″ x 97″ x 66″ |

| Weight | 5401 lbs |

EQUIPPED WITH

| NC Control Panel: Touch Screen Control, 20 Job Presets, Multiple Language Capability, Trouble Shooting Prompts, Easy Operation |

| PLC Control for All Electric and Hydraulic Functions |

| Infinitely Variable Speed Controlled by VFD |

| Hydraulic Retractable Shuttle Vise Material Indexer |

| Rapid and Creep Speed Index Vise Control |

| Multi-Step Full Stroke Vises with Split Front Vise and Variable Vise Pressure Control |

| High Efficiency Transmission |

| Nesting Fixture for Bundle Cutting |

| Spring Loaded, Zero Clearance, Coolant Through, Carbide Faced Saw Guide with Lead-In Rollers |

| Power Driven, Coolant Flushed, Blade Cleaning Wire Brush |

| Flushing Hose and Auxiliary Coolant Nozzles |

| Hydraulic Blade Tensions |

| Blade Breakage/ Stall Motion Detector Shut Off Switch |

| Set Up Tools and Tool Box |

| One DoAll Bi-Metal Saw Blade |

| Complimentary DoAll Cutting Fluids Package |

| Automatic Chip Conveyor |

| Band Door Interlocks |

| Hydraulic System |

| Work Light |